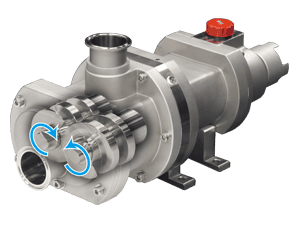

Twin screw pump “GemiL”

GemiL NEW!

Solving all food factory problems at once!

- No liquid shearing & solids breakage by sealed transferring chambersEliminate causes of contamination with no metal-to-metal contact twin screw pump

- Compact body greatly reduces equipment footprint

- Excellent quantifiability even for viscosity changes

- Improved accuracy of high-temperature instant sterilization

- Realizing ideal short time CIP by high-speed rotation of 3600 rpm

Features

- Capable for a wide range of fluids and high temperature

- Securing hygiene by handling clean fluids with contamination-free

- Capable of handling from fine particles to large-sized solids

- Dry operation, self-priming without priming water are possible

- Standardized with quench structure (semi-double seal)

- Easy maintenance(no special tools are required)

- Excellent corrosion resistance with high-grade materials

- Production cost reduction by space-saving

Performance

Applications

Foodstuffs

Soups, dairy & delicatessen industries, confectionery, baked, butter, ice cream, butter, margarine, chocalate, mayonnaise, salad dressing etc

Beverages / Breweries

Fruit juice concentrates (with fruit pieces), wine, cognac, liquors, yeast, syrup, draff

Cosmetic industries

Detergents, shampoo, conditioners, toothpaste, moisturisers, lotions, veseline

Pharmaceutical

Raw material, cell suspension, glucose, glycerine

Working principle

There are no contacting or sliding parts inside the GemiL casing other than the mechanical seal. Internal pump parts are kept at a certain distance during operation, thus, no metal or rubber dusts are generated during operation. Two symmetrical assembled screws (rotor + shaft + bearing) are arranged in parallel form inside the pump casing, and the enclosed spaces (chambers) formed between the inner wall of the casing and the two rotating rotors move in an axial direction. In this process, the inside and outside of the chamber are connected by small gaps. Liquid moves slightly, but solids are confined within the chamber and not cut or deformed during the transferring process. In addition, liquid is continuously transported out of the pump without any shearing force and without impairing the flavor and texture. Separated into 6 closed spaces (chambers) by the rotor, transferring occurs without any shearing force being applied to the pumped liquid.

Dimension Table

Download >> Twin screw pump “GemiL”